Why replace steel guy wires?

Steel guying wires are still very common, however they are heavy, difficult to work with and their strength deteriorates with time due to corrosion and general ageing.

Their electrical conductivity is an undesirable feature as this interacts with the antennas and deteriorates their radiation pattern.

Thanks to the recent developments of materials, both amateur and professional users are changing over to non-conductive guys and ropes and will never go back to using the steel wires once the benefits are fully appreciated. The non-conductive synthetic fibres have all the necessary qualities: high strength, negligible elongation but with good flexibility, long life, low wet-ability, minimum bending radius giving the ability to tie knots, excellent UV radiation resistance, weather durability and resistance to acids and alkali.

MASTRANT® optimized ropes are made from proven modern materials such as Polyester (Mastrant P), Dyneema® (Mastrant-M, Mastrant-D and D-F2) and Vectran®. The product range covers a variety of applications, from thin support lines used for tying wire antennas and beams, to guys for supporting small and portable masts and vertical antennas, to anchoring ropes for high antenna towers tens of metres high. The product line is supplemented by a wide range of stainless steel accessories.

The development, testing and quality control of all these products ensures a superior product delivering long life. They are subject to continuous verifying in real conditions in co-operation with many users.

"Is Mastrant® made from Kevlar?"

People are used to using Kevlar for “high strength ropes with lower elongation". No matter what material the rope is made of. Kevlar (or Technora, Twaron, etc.) are brand names for aramid fibres. Those fibres are susceptible to UV degradation so they are always protected with extruded outer protective jackets - for example Phillystran® HPTG-I.

However, there is another material for ropes for mast guying - Ultra-High Molecular Weight Polyethylene (UHMwPE); trade names are Dyneema® , Spectra® or Nexsteel. It has excellent UV resistance, high knot strength and low specific gravity. Mastrant-M ropes using new Dyneema® Max Technology (by DSM) maximizes the scope of the world’s strongest fiber. Mastrant® is pioneering the use of high performance synthetic rope in permanently loaded applications. Designed specifically for mooring production facilities in deep waters, DSM’s new ‘ultra high strength at low weight’ Dyneema® DM20 fiber delivers unrivalled rope strength, stiffness, durability and longevity.

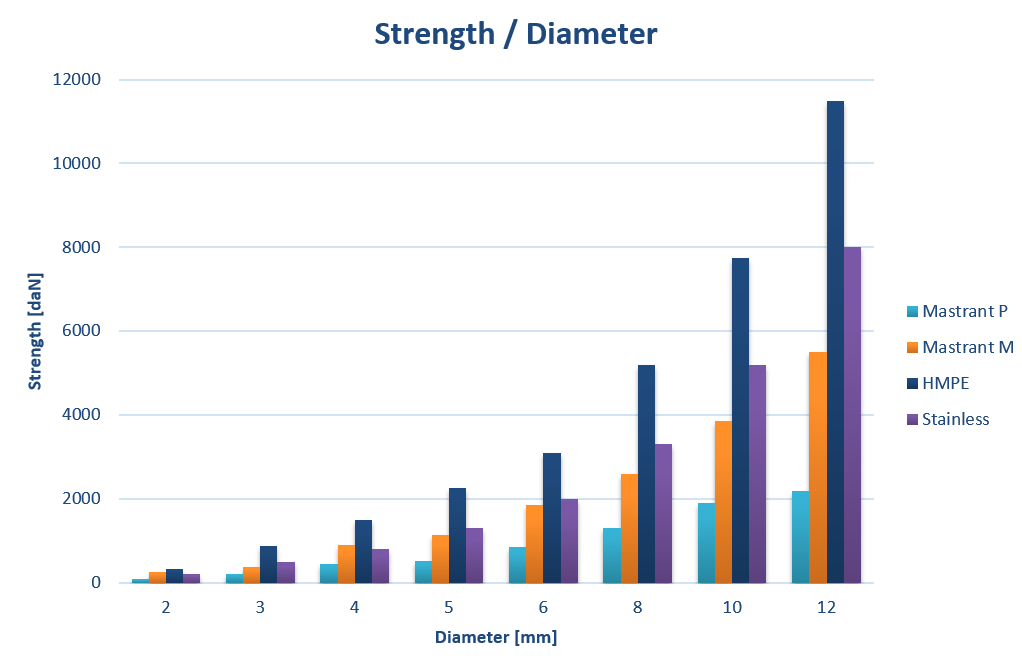

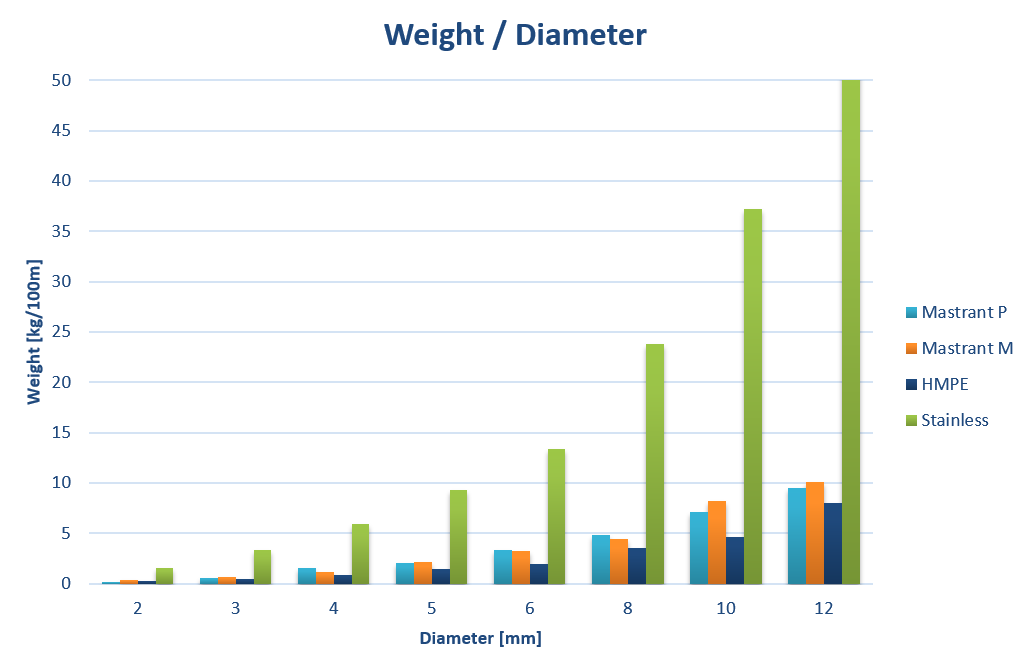

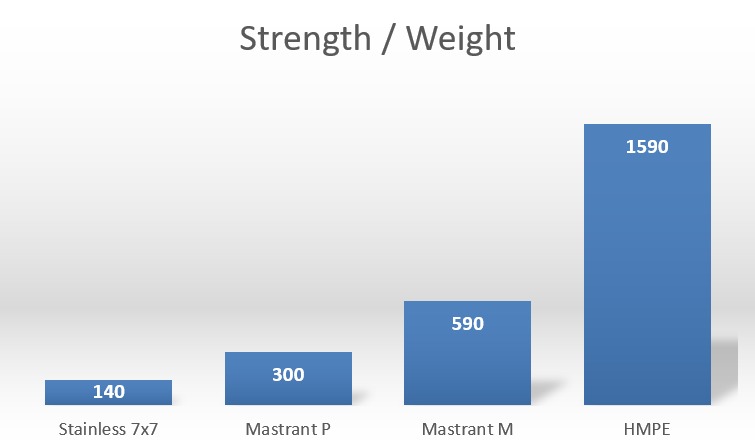

Comparison of Mastrant ropes features

Our direct competitor: hamrope